Fordism: The modern past

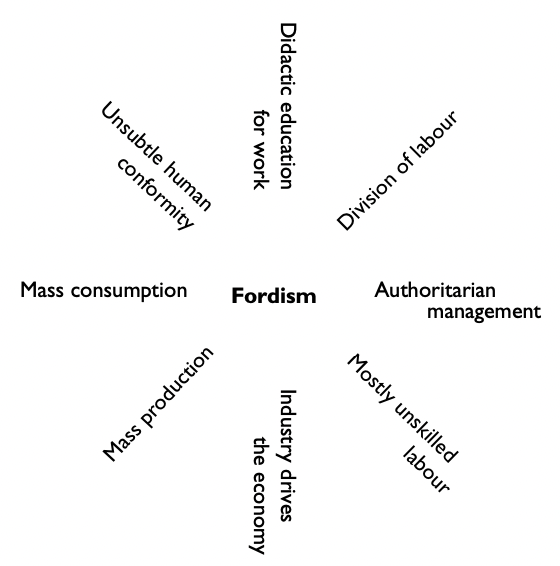

Fordism takes its name from Henry Ford, an iconic as well as a truly influential figure in modern industrial production and organisational management. Here, we analyse the dimensions of Fordist work using the example of his motor car factory.

Dimension 1: Technology

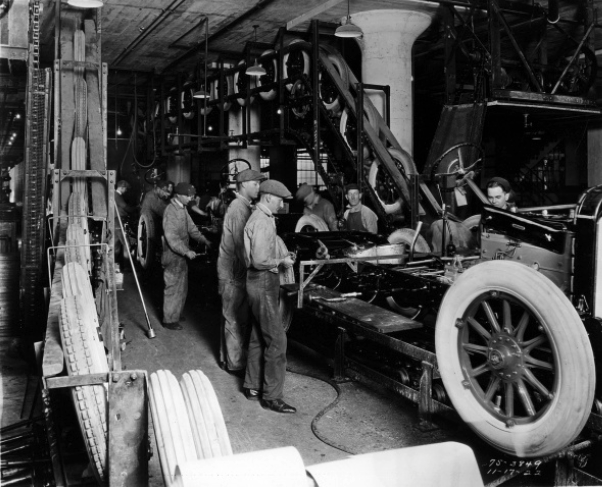

The year is 1920. Ford’s automobile factory is the biggest manufacturing plant the world has ever seen. A famous Model ‘T’ Ford comes off the end of the production line every minute. The scene is one of smokestacks, starting sirens and the relentless movement of the production line.

A massive press stamps crankcases from flat pieces of steel; another produces the 95 tubes for the radiator in one stroke (Jardim 1970). It’s a noisy, smelly and frenetically busy place. The machines of mass production are bigger than any that have ever been built before – more imposing and more productive than ever before. So is the factory system into which they are placed: the huge, integrated corporation undertaking a variety of interconnected tasks.

Henry Ford becomes a rich man, and this because he owns all that physical plant, the fixed capital. This is his technology. The workers do the work, but he owns the plant and, for this reason, the profits are his for the taking.

See Henry Ford on His Car Factory.

Dimension 2: Management

The modern industrial plant, says Henry Ford, requires the most rigid of discipline. It is ‘so highly specialised and one part so dependent on the other that we could not for a moment consider allowing the men to have their own way’ (Ford 1922).

The Fordist factory runs on strict lines of command. It is uncompromisingly hierarchical. Behind the work of every person is the hidden hand of the engineer who designed the machine, and behind him the orders of the boss. The workplace is structured like a giant pyramid, with departments, and divisions within departments, and branches within divisions, and sections within branches. At each layer of the hierarchy, a lesser boss reports to a bigger boss one level up in the hierarchy. The ultimate source of all the orders is Ford himself, at the head of a vertical chain of command. This is where the buck stops, and where the profits go.

Nothing beyond minimal exertion and thinking is expected of the vast majority of the thousands of workers in Ford’s factory. All you have to do, indeed, all you can do, is take orders. Insert this bolt, tighten this nut. Then the production line moves and you do it again.

The underlying management principles of modern industrial plants such as Ford’s are perhaps articulated most clearly by Frederick Winslow Taylor. He devises a set of principles that he calls ‘scientific management’. By measuring ‘time and motion’ of the workers, the manager can devise new ways of getting them to do more work in less time. Taylor is insistent this is not something the workers can work out for themselves. It is the function of the manager to work it out and then tell the worker what to do.

See Frederick Winslow Taylor on ‘Scientific Management’.

Dimension 3: Workers’ education and skills

The skills and capacities required of most workers in Ford’s factory were minimal. Technical knowledge was handed down to the many on the factory floor by the few who sat in offices designing the product, configuring the production line and engineering the ever-finer division of labour. Henry Ford claimed that only one percent of his workforce needed more than one year of training. The rest, he was proud to say, did not need much at all in the way of human skills and capacities.

This was the ingenious paradox of Ford’s factory: his workers were producing one of the most complicated products ever created, but the human skills required of almost all of them were minimal. A factory of predominantly unskilled workers was producing an item of unprecedented technological sophistication. This was achieved by reining the division of labour, creating more and more tasks or steps on the pro- duction line, each of which required less and less skill.

In 1908, just before the introduction of the Model T, the average length of the task cycle of a Ford assembler was 8.56 hours, as each person worked on a large component of the car. Cars were built using methods not unlike those of the coach builders who had for centuries built horse-drawn vehicles, employing skilled artisans who knew how to work with wood and metal, how to make a wheel, an axle and the body of a vehicle. After the introduction of the moving assembly line in 1913, the average task cycle went down to 1.19 minutes (Womack, Jones, and Roos 1990). One worker put this particular panel in place and the next person on the production line the next panel. Which worker and which panel were all determined centrally, in a technological sense by the engineers who designed the production line, and in an organisational sense by the managers. The worker was told what to do, or more likely shown what to do, given that the workforce was predominantly immigrant and not necessarily proficient in English. From the point of view of the organisation, human beings were reduced to a lowest common denominator as unskilled bodies with raw working capacities. From the point of view of the production process, all human beings were the same; they had the same basic physiological capacities.

The results appeared to be nothing short of miraculous. In the 1913 financial year, the 14366 workers in the Ford Motor Company produced 168304 Model T Fords. In 1914, 12880 workers produced 248307 Model T Fords (Jardim 1970). In one year, each worker produced nearly 12 cars. In the next year, each worker produced more than 19. And from one year to the next, the skill level of the workers did not increase. The skill was in the giant, interconnected arrangement of machines that was the production line.

Getting a job in Ford’s factory, the largest and most sophisticated workplace the world had ever seen, was relatively easy. If you were a new migrant to the United States who spoke very little English, the supervisor could tell you what to do by showing you with a few gestures. You could start on the production line just by being put there and being shown which piece to put where.

It didn’t matter that the next person on the line spoke a different language from you – which they often did in the Ford factory, filled as it was with unskilled immigrant workers. Vertical communications were all that mattered, and these were minimal. In fact, horizontal communications were viewed with suspicion by employers such as Henry Ford. They might breed complaint, and complaint could lead to unionism, and unionism to revolution, and revolution to communism. The massive co-location of living, breathing, thinking human beings created a new community capable of articulating what was inhuman about their experience of work, seeking improvements to their working condition. At times, they might even dare to dream of a paradise on Earth, freed of the hardships they experienced in earning their daily bread.

See Karl Marx and Frederick Engels on Industrial Capitalism.

What kind of education system would work best for the Fordist factory? The schools of the first phase of mass, institutionalised education were themselves workplaces in the Fordist mould – places where teachers and students worked in conditions not dis- similar in their general social arrangement from the workplaces of the modern industrial system. The state determined the syllabus; the teachers led their students through the textbooks; and the students were assessed against the correct answers, which had been centrally determined by the educational bosses. From a managerial point of view, the first modern schools were like Ford’s factory – they had a command structure in which teachers had little scope to teach anything that was in any way beyond what they had been ordered to do by the education system, and students had to learn what they were told. The classroom was a place of surveillance and discipline, where students were taught to take the orders of teachers and uncritically to respect authority.

See Michel Foucault on the Power Dynamics in Modern Institutions.

The classroom of didactic teaching was itself a site that prefigured for children many aspects of the world of adult work. In the era of Fordism, the syllabus systematically divided the curriculum into its component parts (not unlike the task cycles of Ford’s production line), transmitted it to students bit by bit, and then assessed to see what the student had learned.

As discussed in Chapter 2 during our exploration of didactic education, this type of education produced two possible outcomes, both of which made a certain kind of sense in the era of Fordism. A few did well at school, got good grades and were put into the top stream. These few were destined to become the managers and the engineers. Perhaps taken to the level of diploma or even, occasionally, a university degree, this education was a once-in-a-lifetime opportunity to learn professional or trade knowledge that would last for life. Any other learning could be left to life experience.

The majority did not do so well at school. ‘If only I had done better at school ...,’ they might say to themselves, wistfully, believing for a moment that they really had the chance of a better job. At best, school had taught them a few values: to be punctual, to be disciplined, to take orders and to respect received knowledge. School might also provide them with a few ‘basic’ skills, such as the minimal reading, writing and arithmetic sometimes required to make their way in modern work.

See Going to School in Richmond, 1900.

Dimension 4: Markets and society

‘Any colour you like as long as it is black,’ said the phlegmatic Mr Ford, who paid his workers $5 a day. This was good pay, he told them, and now that production had become so efficient and the price had come down to $500, enough to be able to afford a Model T. The economies of scale of mass production made it possible to produce consumer goods cheaply enough to create a mass market. Churning out the same product in huge numbers, day in and day out, Ford was able to produce a cheaper and cheaper car – so cheap, in fact, that even the lowliest of his workers could afford one.

Consumers, in this system, had to be thought of as a uniform mass market. Henry Ford had worked out what was good for the consumer: a basic car, always black. No need for choice; he was going to give them what he thought was good for them. Mass production begat mass consumption, and with this came a series of cultural assumptions about the universal and homogeneous interests of modern people. As their needs were identical, the product could be identical. The same, Ford determined, was good for all and good enough.

In 1915, Henry Ford set up the Ford English School. All foreign workers in his factory had to attend. The first sentence they were taught was ‘I am a good American.’ At one of the school’s graduation ceremonies, a great melting pot (labelled as such) occupied the middle of the stage. A long column of immigrant students descended into the pot from backstage, clad in outlandish garb and flaunting signs proclaiming their fatherlands. Simultaneously from either side of the pot another stream of men emerged, each prosperously dressed in identical suits of clothes and each carrying a little American flag (Bernstein 1994).

Immigrants – the poor and the hopeful – would come to the United States and start work in Ford’s enormous factory. People of different cultures, languages and nationalities would all work together in the factory in the same kinds of ways, mostly earning roughly the same pay. In the end, they would have the choice of buying the same car. They would also assimilate to the American Way of Life. Underlying Fordism was a philosophy of cultural uniformity.

At most, cultural and linguistic differences were used as a divide-and-rule tactic, deliberately putting workers who spoke different languages beside each other on the production line, for example. Gender differences were addressed in the Fordist workplace with a similarly two-faced ambivalence. In one moment, the Fordist organisation was gender blind; women and men are equally capable of working on the production line. In another, men did the managing and women, before they married at least, were secretaries and tea ladies or – perhaps, if they weren’t to work in a factory – nurses or school teachers.

Although people entering industrial work for the first time experienced new-found affluence, this was a deeply unequal society. Women may have felt liberated as they earned their first pay packet. Immigrants fleeing poverty and war-stricken countries found themselves able to purchase small but previously unthinkable luxuries. But while they became more affluent in minor ways, their bosses became wealthier in fabulous ways, profiting hugely from the productivity of their workers and the scale of the mass markets for which they were producing. The relatively good times, however, never seemed to last that long, as the whole system periodically lurched into recession and war. It was at these times particularly that the system looked less attractive to ordinary workers. This was when they began to think of unions, of social democracy or even of a communist utopia in which the workers took control of the factories and distributed the fruits of their labours equally among themselves.

There are parallels and functional connections between didactic teaching and Fordism. This was the social context in which mass, institutionalised schooling emerged. Didactic education on a mass scale and Fordist work are social innovations born of the same historic moment. Even today, there are places where Fordism and didactic education continue to work together as a functional pair. At other times they appear to be anachronistic flashbacks to a world that is all too familiar but in dire need of renovation and renewal.